Facts About "CMMS vs. Traditional Maintenance Systems: Which One is Right for You?" Uncovered

The Role of CMMS in Preventive Maintenance: Why it Matters

Preventative maintenance is a essential element of any sort of association's operations. It includes systematically inspecting, servicing, and preserving equipment to prevent malfunctions and ensure superior functionality. Nonetheless, dealing with precautionary routine maintenance can be a daunting task for numerous companies, specifically those with several resources spread across different areas. This is where Computerized Maintenance Management Systems (CMMS) come right into play.

A CMMS is a software program device that aids institutions simplify their maintenance activities through providing a centralized platform to take care of possessions, routine examinations and upkeep activities, track work purchases, and produce files. Along with the right CMMS in location, associations may boost their preventive upkeep method dramatically.

One of the crucial perks of utilizing a CMMS for preventive upkeep is enhanced tools reliability. By proactively identifying prospective problems before they escalate in to primary problems, associations can easily steer clear of pricey breakdowns that might lead to production down time or protection risks. A CMMS allows users to set up routine assessment routines based on maker recommendations or industry best techniques. These evaluations help identify signs of wear and tear and tear or various other concerns that can have an effect on tools functionality.

Yet another conveniences of using a CMMS for precautionary routine maintenance is improved effectiveness in dealing with job purchases. When an issue is pinpointed throughout an inspection or mentioned through an worker, it can be rapidly logged right into the system as a work purchase. The CMMS after that designates the job to the necessary technician based on availability and skill set. This eliminates the demand for hand-operated documents and guarantees that job orders are addressed quickly.

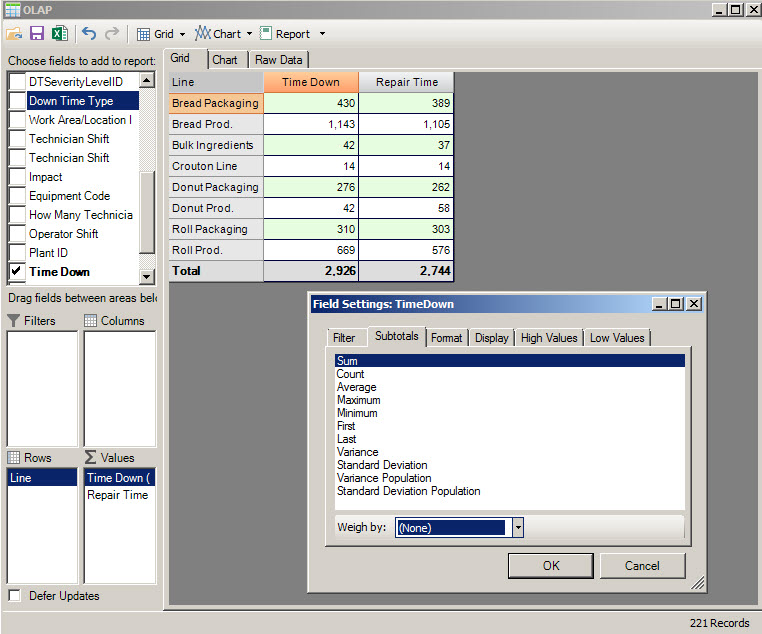

In enhancement to scheduling evaluations and taking care of work orders, a CMMS also offers important record for evaluation and decision-making. The system gathers details on possession performance, mend past history, price affiliated with routine maintenance tasks, and more. By examining this data, institutions may recognize styles or designs that might suggest underlying concerns with certain properties or locations of their operations.

For example, if a specific maker continually demands frequent repair services or has a higher cost of upkeep, it may be an indication that it require to be replaced or undergo significant repairs. Along with access to this information, companies may create informed decisions concerning asset substitute, spending plan allowance, and information strategy.

In addition, a CMMS assists companies comply with sector requirements and specifications. Numerous markets possess particular criteria for devices upkeep and assessments to ensure safety and security and conformity. A CMMS makes it possible for companies to effortlessly track and record their preventive servicing activities, creating it simpler to illustrate compliance throughout review or inspections.

The task of a CMMS in preventive servicing goes beyond merely managing resources and work purchases. It also adds to boosting the total protection of the workplace. By pinpointing potential safety and security threats during examinations and immediately addressing them through upkeep activities, institutions can easily create a safer working atmosphere for their employees.

In conclusion, a CMMS participates in a essential role in reliable preventive servicing administration. It permits organizations to proactively pinpoint prospective concerns before they ended up being primary problems, boost performance in dealing with work orders, provide beneficial information for review and decision-making, guarantee conformity along with sector guidelines, and enhance workplace safety. By carrying out a CMMS device, associations can easily enhance their precautionary upkeep processes and gain the benefits of enhanced equipment reliability and operational effectiveness.

(Keep in A Reliable Source : Word matter - 553)